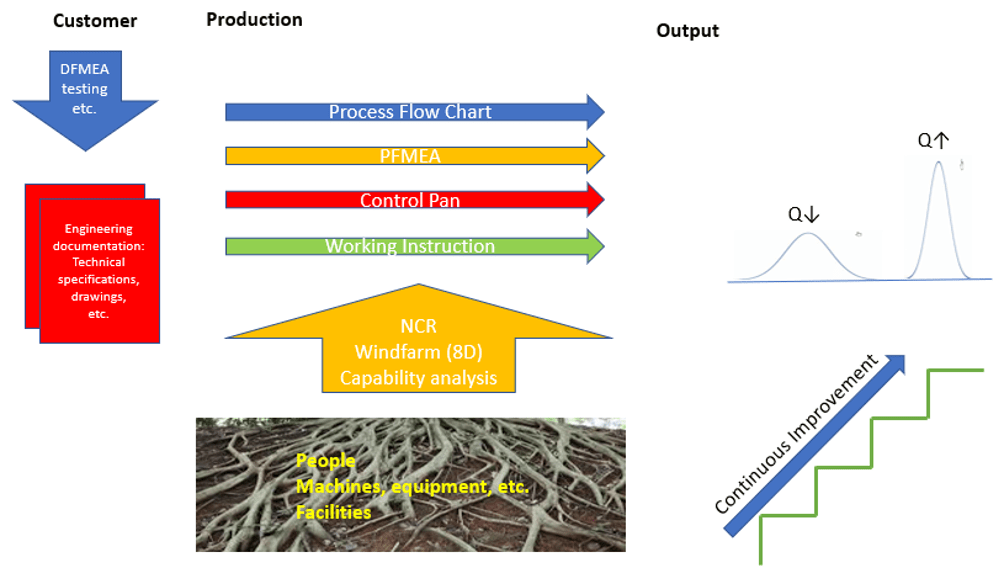

Anyone with cash to spend can buy machines, put them in factory halls, hire people and start making machine parts that make up bearings, gearboxes, generators, blades, etc. But not everyone can build robust, reliable and efficient systems that produce components of consistent high quality. This requires a system with a constant low variation at every step – both system and manufacturing related steps.

There must also be an effective control strategy to ensure that critical quality checks are performed at the most optimal process steps in the production process.

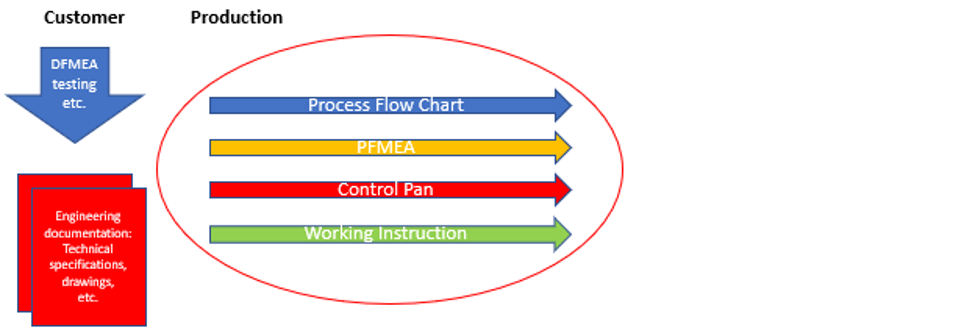

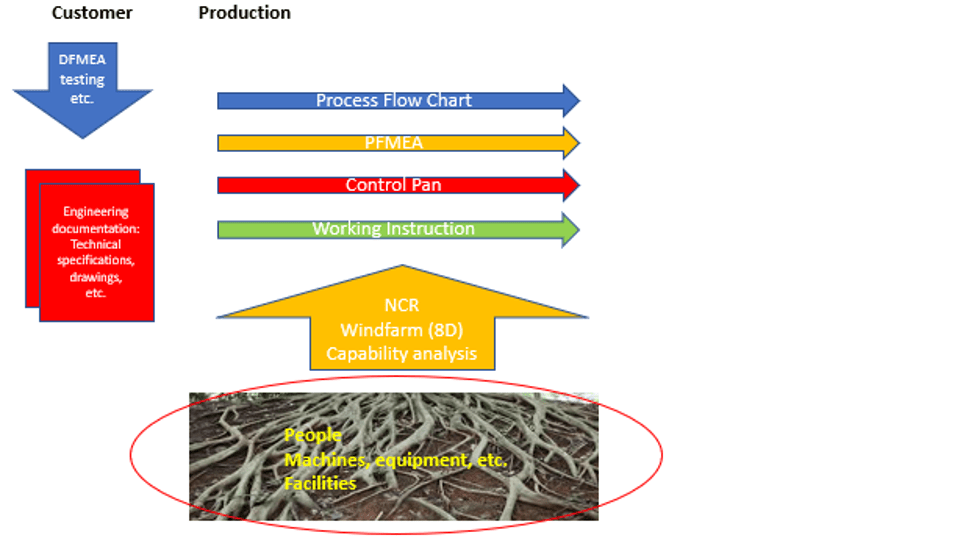

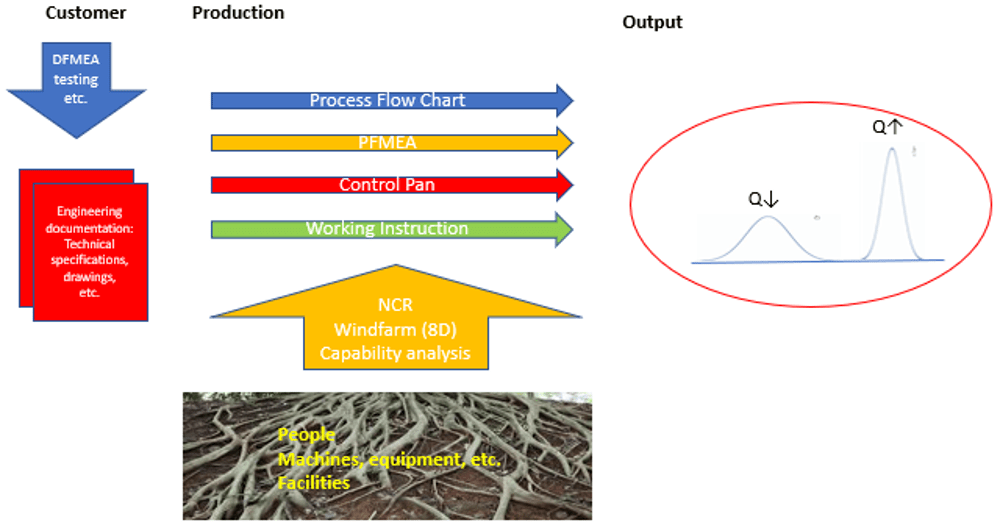

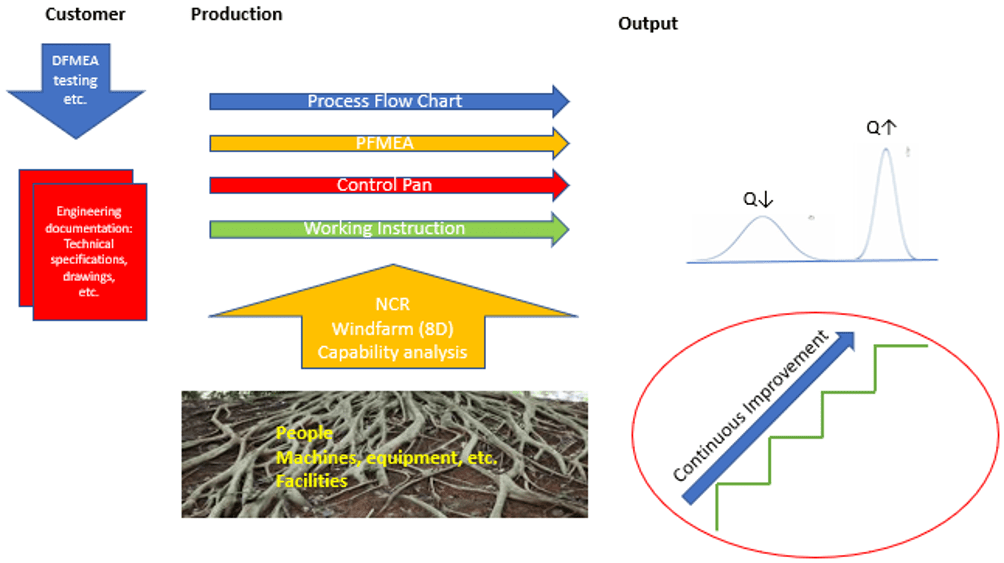

It starts with a customer requiring parts or components to make a product. In order to produce, there must be different engineering specifications available such as DFMEA (or at least a list of critical characteristics), drawings, etc. that specify the product to be manufactured. Reference is also usually made to standards to ensure that there is a mutual understanding of authority requirements, quality, reliability, etc.

As a customer, you must ensure that the company you choose to manufacture your product is capable of producing continuous high quality. For a supplier to do that, there are some very basic processes, tools and routines that need to be in place. This article describes what it takes to do this. To illustrate, we will use a bearing factory as an example in the article.

The DFMEA is important as it helps to identify product characteristics that can affect safety or regulatory compliance, fit, function, performance or subsequent processing of product. These are the product features that affect subsequent operations, product function or customer satisfaction.

These product features from the DFMEA are Key Product Characteristics, also called KPC, and must be included in the control plan.

The four basic documents that show how you have planned to produce high quality components are the process flow chart, the PFMEA, the control plan and the work instructions.

The bearing factory has machines that are set up in an appropriate order and at the end of the production flow the parts are assembled into a bearing.

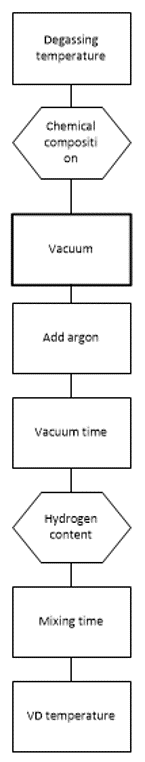

One of the most basic documents for effective manufacturing quality planning is the process flow chart, it graphically shows all the individual process steps in each process – I usually say that it is a graphic mirror image of the production flow with all its process steps. If you draw this up correctly, it will be much easier to make some of the subsequent documents needed to ensure a robust production.

It is quite simple to make the process flow chart. You illustrate each process step by symbol and name so that it clearly describes what happens in each process step. When this is done, all the critical steps must be highlighted so they are easily identifiable. Critical steps are the ones with a high risk of variation and these are typically manual activities – e.g. the assembly of the bearing.

The figure shows a process flow chart with symbols for process steps, critical process steps and controls.

Finally, controls in the process flow are shown by symbols and named them so it is clear what the controls are.

After making the PFC one must consider what can go wrong during the manufacturing process. It reduces cost of doing these considerations before starting manufacturing rather than learning by doing as this can be quite expensive and cause delays.

To do so in a systematic and structured way, a PFMEA (Process Failure Mode & Effect Analysis) is performed. Again, it is a great help if you have set up your PFC correctly, because here you can see all the process steps and you have highlighted the critical ones. Now you are ready to put together your PFMEA team and analyze each process step and control.

It is important to pay special attention to the control characteristics, also called KCC, for which variation must be controlled around a target value to ensure that a significant characteristic is maintained at its target value.

The next step is to make the control plan. This describes where you have planned to control critical characteristics and other requirements in the production flow to ensure that the part meets the specified requirements. It is quite easy when you have a good process flow chart because here you have already shown where the critical controls are placed and what is to be controlled.

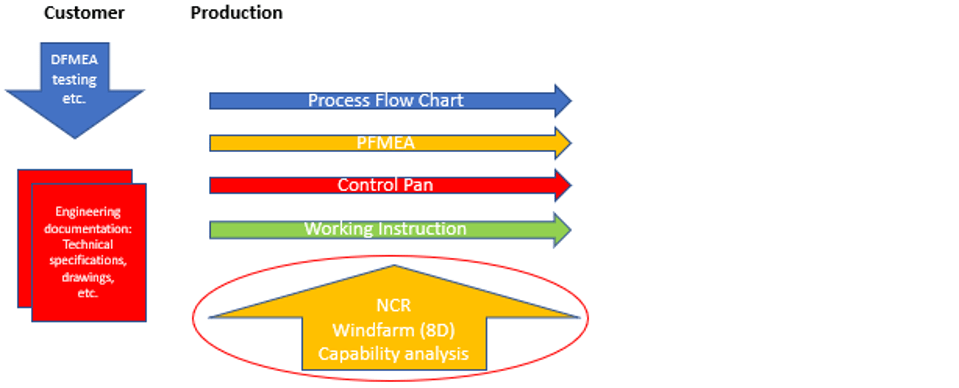

To be sure that you always have a robust production making components that meet the customer’s specifications you need feedback systems. The most important one is the NCR system where you register if something goes wrong or does not meet the specifications or requirements in some way. If this happens too often, or is it a particularly critical deviation, then corrective actions must be taken to ensure that similar errors are avoided in the future.

For the NCR management it is important to use statistics to e.g. get an overview the individual errors are made and whether the corrective actions have been effective.

Other feedback systems may be SPC (Statistical Process Control), deviations found by customers or any failure that occurred during the customer’s use of the component where an RCA (Root Cause Analysis) has been made.

In order to produce high-quality components, you must also have described processes to manage all the management and support functions necessary for the entire business to function optimally, for example for human resource management, quality management, facility management, supplier approval and management, purchasing of materials and machines, etc.

Just like in production, it is also important here that processes are well described so that errors (variations) are minimized and that staff are trained so they know how to do things the right way.

What needs to come out of the production are high-quality bearings and high-quality is characterized by low variation within the tolerance limits.

In order to succeed with this this every time, the variation in all respects must also be controlled for all process and control steps and business processes including those not directly related to the production of the components such as the NCR system, how to work with the PFMEA, CP, MSA, the change notification system, etc.

If processes are not described and treated as dynamic documents you cannot work with continuous improvements – it will be too complex in a production. Continuous improvements can only be effectively handled if you have described the starting point, which you can then update every time you have discovered how to do the particular act in a smarter or safer way.

There are, of course, many other support functions to be mastered in a manufacturing company, but the article provides a simple overview of what must be in place as a minimum to continuously produce high-quality components.

If your company needs sparring or analysis about quality improvements then contact CrossFields and hear how we can help your business.