The example below deals with offshore wind farms, but i could just as well have been about many other types of assets.

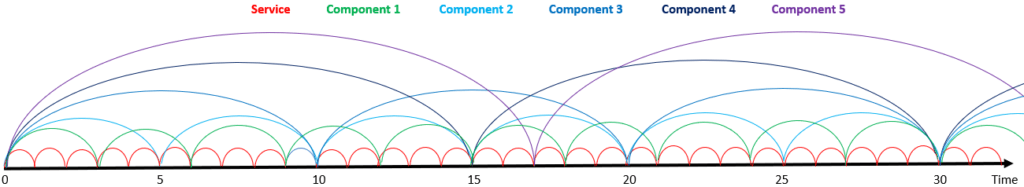

One of the advantages of preventive maintenance is that you can bundle components that need replacing, saving time and visits. When bundling, you should make sure that it coincides with the annual service visits, so that the need for logistics is further reduced.

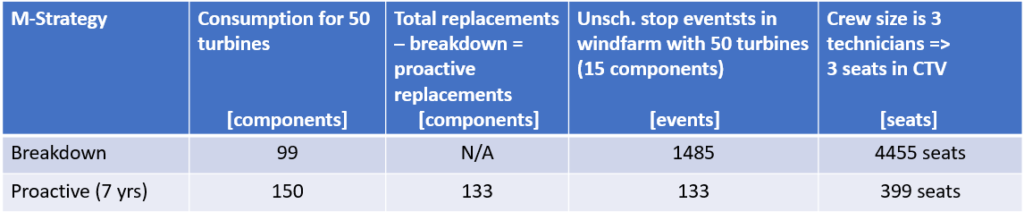

Something that is not always properly understood is that the chosen maintenance strategy controls the need for e.g. crew transfer vessels (CTV). This means that you need to optimize your strategy before drawing a CTV contract, or you may end up with an overpriced CTV contract or even a contract based on a poor maintenance strategy – both can result in a poorer business case than one might alternatively have had.

Often, you can optimize your annual service and thus make time for proactive replacements without extra time cost. This means that in many cases you may need much less CTV capacity and spend the annual service time taking care of proactive replacements which means far fewer visits to the wind farm.

The benefits are:

– Lower OPEX (cheaper CTV contract and less need for constant crew preparedness)

– Higher availability (far fewer stops)

– Less risk of injuries (HSE), fewer visits to wind turbines lead to less opportunities for injuries

– Minor emissions to the environment due to reduced need for CTV capacity

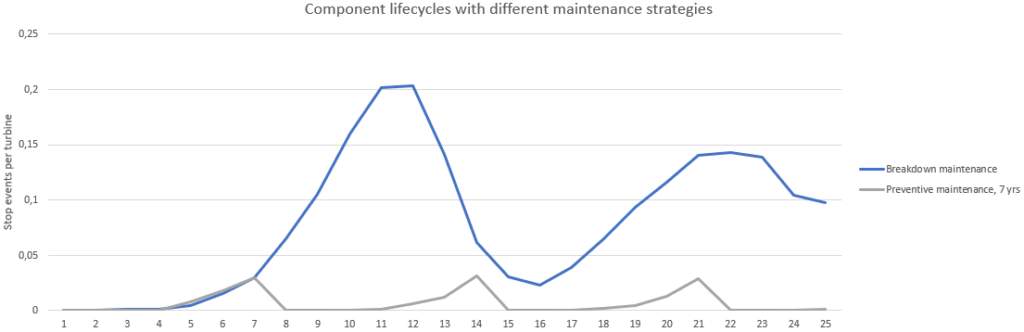

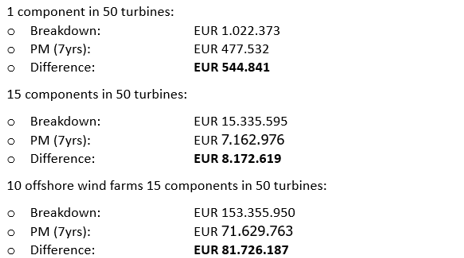

Conditions of calculation in Figure 3

- All inputs in the simulation come from a generator fan at EUR 500.

- Does not include the effect of bundling

- CTV cost is not included

- The loss of lost production is included

In the example I have used 15 components in 50 wind turbines, it could as well have been 30 or 60 components in 100 turbines ….

As you can see, there is a lot of money in choosing a preventive maintenance strategy as well as bundling. You avoid firefighting and it may even have the positive side effect that when there is no fire the fire station is a boring place to be and, in turn, more money is earnt.